PVC Resin SG-3 High K-Value Engineered for High-Strength And High-Impact Applications

| Availability: | |

|---|---|

Product Name: Hengtong PVC Resin HT 1200 SG-3

Brand: Hengtong, Xingfa

Process Type: Ethylene-Based PVC Resin

Packaging: 25 kg/bag ,1000 kg/bag

Technical Specifications & Grades

| Property & Test Condition | Specification Range | Standard Test Method |

|---|---|---|

| K-Value | 74 - 76 | ISO 1628-2 |

| Average Degree of Polymerization (P) | 1150 - 1250 | ISO 1628-2 |

| Viscosity Number (mL/g) | 118 - 126 | ISO 1628-2 |

| Bulk Density (g/cm³) | 0.44 - 0.52 | ISO 60 |

| Volatile Matter Content (% max) | 0.40 | ISO 1269 |

| Sieve Residue (% max) - 63 μm Sieve - 250 μm Sieve (min) |

0.2 99.0 |

ISO 4610 |

| Whiteness (Hunter, % min) | 90 | Hunter Method |

| Fish Eyes (count/400 cm², max) | 20 | ASTM D 3596 |

| Residual VCM (ppm, max) | 1 (Food Grade compliant) | GC Method |

Key Features & Benefits for Extrusion Manufacturers

Unmatched Mechanical Performance: High K-value delivers superior tensile strength, stiffness, and long-term creep resistance, ensuring product integrity under stress.

Superior Impact Resistance: Excellent inherent toughness makes it ideal for applications prone to mechanical shock or pressure, significantly reducing failure rates.

Enhanced Thermal Properties: Higher Vicat Softening Temperature provides improved dimensional stability in high-temperature environments and during hot-fill processes.

High Purity & Clarity: Low fish eye count and exceptional purity allow for the production of crystal-clear products, perfect for premium packaging.

Excellent Processability: Free-flowing powder with a porous structure ensures rapid, uniform dry blending, efficient gelation, and smooth processing in extrusion, injection moulding, and blow moulding.

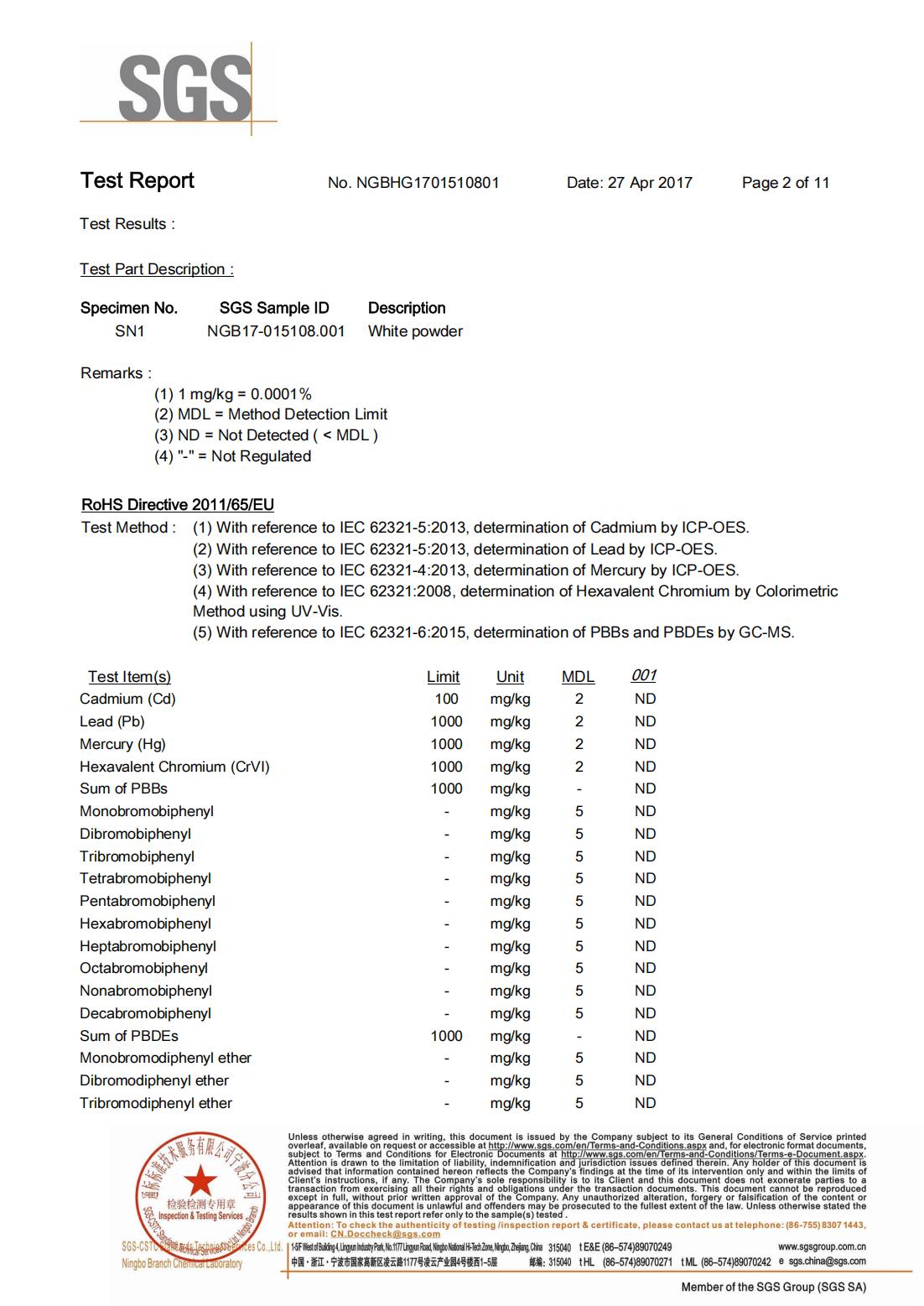

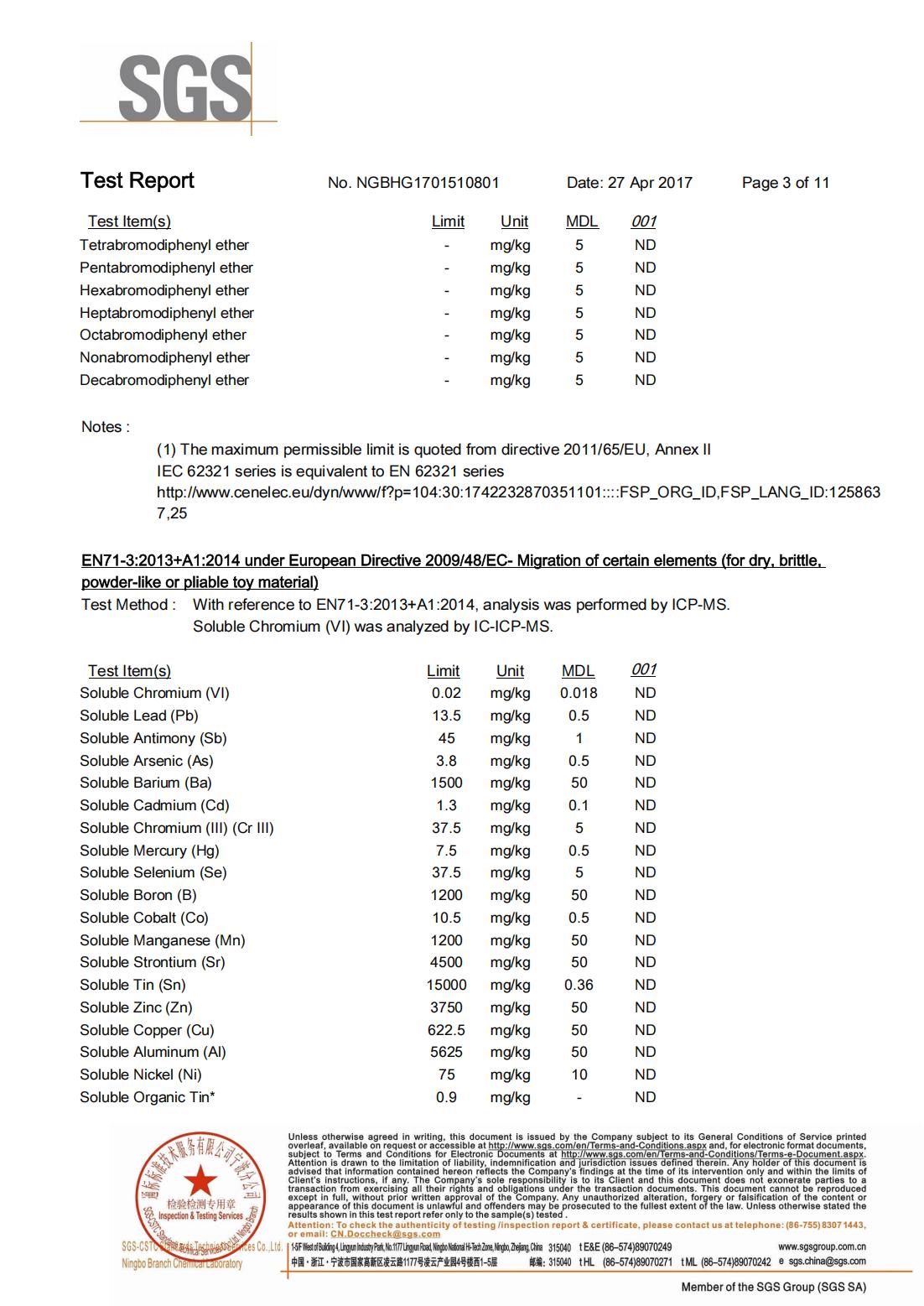

Regulatory Compliance: We offer standard and food-grade qualities that comply with major international standards, including FDA, EFSA, and REACH for specific applications.

Applications

SG-3 resin is the material of choice for engineers and product developers requiring enhanced performance:

Blow Moulding:

Clear Bottles: Mineral water, edible oil, vinegar, and pharmaceutical bottles.

Technical Containers: Chemical and industrial packaging.

Extrusion:

High-Pressure Pipes: Industrial and chemical pressure pipes.

Profile & Sheet Extrusion: High-strength technical profiles, solid sheets for construction and fabrication.

Cable & Wire: Insulation and jacketing requiring good mechanical properties.

Injection Moulding:

Robust Fittings: High-performance pipe fittings, valves, and mechanical parts.

Technical Parts: Durable components for appliances and automotive interiors.

Calendering:

Rigid Sheets & Foam Boards: For signage, chemical storage tanks, and partitioning.

Processing Recommendations

Blending: Excellent dry blend characteristics. Standard mixing sequences apply.

Extrusion: Requires a robust twin-screw extruder. Processing temperatures are typically 5-15°C higher than for standard K67 resin to achieve optimal fusion. Ensure adequate lubrication balance.

Injection Moulding: Higher injection pressures and temperatures may be required compared to lower K-value resins.

Blow Moulding: Excellent parison control and melt strength for consistent bottle production.

Note: We highly recommend conducting trials to fine-tune your specific formulation and machine parameters for optimal results.

Why Choose Our SG-3 Resin?

Consistent Quality: State-of-the-art manufacturing ensures batch-to-batch consistency.

Global Standards: Products meet and exceed international quality and safety regulations.

Technical Expertise: Dedicated support team to help you solve processing challenges and optimize your formulations.

Competitive Pricing: Direct-factory pricing ensures you receive the best value without compromising on quality.